Preparation and production of electronic ink materials

Electronic paper is an ultra-thin, ultra-light display capable of flexible display and zero-power image retention. It aims to be an alternative to regular paper. E-paper can be realized in a variety of ways, the most important of which is to use printing technology to make e-paper by coating a complex liquid called "e-ink" on a flexible substrate.

Electronic ink is an ink-like suspended object that takes on different stable states under different voltages of different polarity, thus showing different colors and grayscales. Reversible, bistable and flexible display can be realized under the action of external electric field. The concept of electronic ink is presented by the MIT media lab, the idea was initially microcapsule electrophoretic display materials, but the realization of electronic ink way more than that, after a period of rapid development, electronic ink has developed into a concept connotation quite rich, gradually into the electronic paper. All flexible bistable display materials are commonly referred to as electronic ink.

Preparation of electrophoretic display microcapsules as principle of electronic ink material, the material in the capsule around the dye as light particles of foreground and background color of the dispersion medium, when applying an electric field, the particles under the action of electric field force, movement to capsule front end, capsule front end with the color of the particles, when applying another electric field, particle movement to capsule back end, The front end of the capsule thus takes on the color of a dispersed medium. Countless of these capsules can be lined up to display images. When the external electric field is removed, due to the interaction between the particles and between the particles and the wall of the microcapsule, the particles can maintain their state when the electric field is added, and the electric field energy is not needed to maintain their display, so as to achieve bistable state.

The structure of the e-ink material can be summarized as an electrophoretic display solution wrapped in microcapsules, including electrophoresis particles, dispersion medium, charge control agent and dispersant.

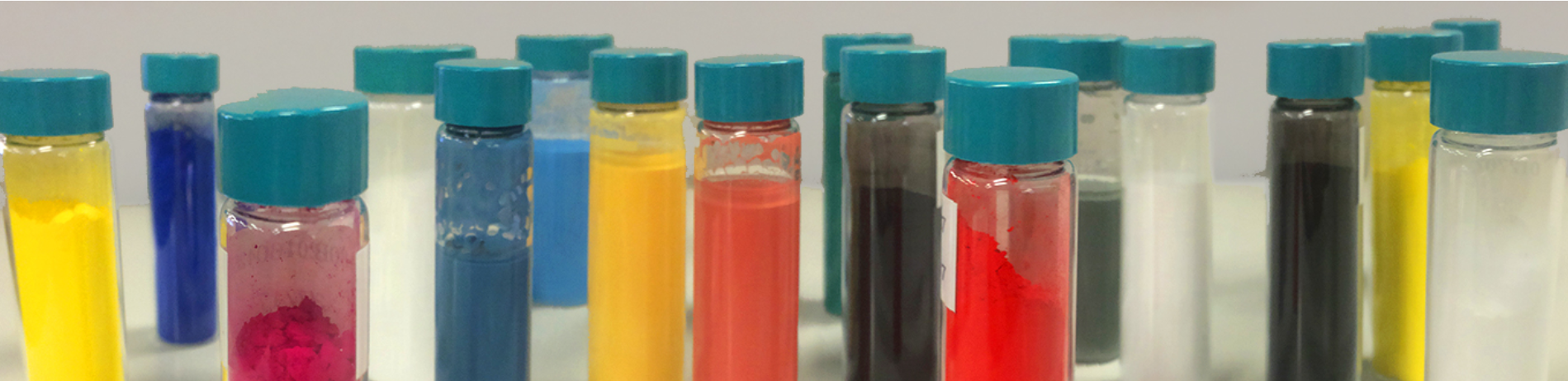

We have studied the preparation of electrophoretic particles and the choice of modified dispersion medium, the choice of charge control agent and the best amount of microencapsulation of electrophoretic display liquid and the preparation of formaldehyde resin based e-ink materials by a novel method. Work mainly chooses a sol gel preparation of nano-silica qin as electrophoretic particles, particles on the particle package poly (methyl acrylic acid armour cool, polyvinyl alcohol or with stearic acid surface modification of oxide khin selection is given priority to with tetrachloroethylene, and toluene, three toluene, cyclohexane to match with the preparation of dispersing medium, The viscosity, dielectric constant and other properties of different proportions of the compound dispersion medium were studied. Sodium dodecyl benzene sulfonate, cetyl trimethyl ocracan and a charge control agent were selected. Electrophoretic display liquid was prepared.

Abstract: Electronic ink microcapsules were prepared by in-situ polymerization using formaldehyde resin as capsule wall material. An improved in situ polymerization method was also developed for microencapsulation of the electrophoretic display liquid by using water-soluble formaldehyde resin with low molecular weight instead of the prepolymer as the reaction monomer. This method has the advantages of high yield and smooth surface. This method preparation of formaldehyde resin capsules in the key with the preparation of appropriate low molecular weight water-soluble formaldehyde resin, so we studied the formaldehyde resin synthesis reaction, temperature, time, value, urea formaldehyde mole ratio and other reaction conditions on the resin viscosity and surface activity.

The effects of reaction conditions during microencapsulation and surface activity of low molecular weight formaldehyde resin as monomer on encapsulation efficiency were studied. A novel method was used to prepare electronic ink materials. The electrophoretic display solution was dispersed in the low molecular weight formaldehyde resin, stirred to make it into emulsion, and then heated to initiate polymerization. After the reaction was completed, the electrophoretic display solution was separated and encapsulated in the transparent formaldehyde resin.

This method eliminates the preparation of capsule process, a molding, simple technology. The most important step in the preparation of formaldehyde - based e-ink materials is to prepare formaldehyde resin with appropriate viscosity. The effects of reaction conditions such as temperature, time, value and formaldehyde molar ratio of urea on resin viscosity were studied. According to the above method, a transparent and dense vein formaldehyde-based electronic ink material was prepared, and its electric field response was studied by using parallel plate electrode. When the electric field intensity was 125V/MM, the electric field response time of particles was less than 0.5 seconds