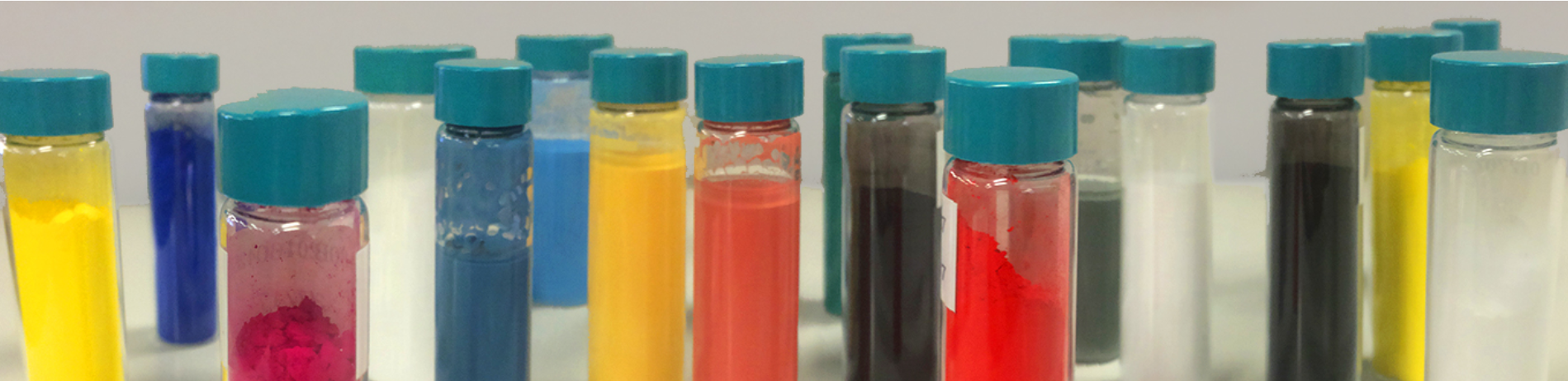

Several methods of preparing electronic ink microcapsules

Preparation of e ink microcapsules by complex condensation method

1.00g acacia and 1.00g gelatin were dissolved in 50mL water at 50℃ respectively, and then the gelatin solution was slowly added to the acacia solution. At a stirring speed greater than 400rpm, 4mL of the electrophoretic dispersion prepared above was added to the aqueous phase for emulsification for 20min, then the stirring speed was reduced to 200rpm, the pH was adjusted to 4.4 with 10% acetic acid solution, and the reaction temperature was reduced to 10℃. Then 3mL of 5% glutaraldehyde solution was added and stirred for 60min. Add 0.40g sodium carboxymethyl cellulose, adjust pH=8~9 with 10% sodium hydroxide solution, the reaction temperature rises to 50℃, stir for 60min, get the microcapsules containing electrophoretic dispersion, wash the microcapsules with water for many times, that is, electronic Ink (GA-E-INK) microcapsules prepared by complex condensation method.

Electronic ink microcapsules were prepared by in-situ polymerization

0.50g (4.54mmol) resorcinol and 5.00g (83.33mmol) urea were added to 200mL water dissolved with 0.20g gelatin, and the pH was adjusted to 1.5~2.0 with 10% hydrochloric acid solution. At a stirring speed of more than 400rpm, 4mL of the electrophoretic dispersion prepared above was added to the aqueous phase and emulsified for 20min, and the reaction temperature rose to 60℃. 12.22g (150.71mmol) 37% formaldehyde solution was added and stirred for 2h to obtain microcapsules containing electrophoretic dispersion. The microcapsules were washed with water for several times to obtain electronic Ink (UF-E-INK) microcapsules prepared by in-situ polymerization method.

Electronic ink microcapsules were prepared by interfacial polymerization

Taking 4mL of the electrophoretic dispersion prepared above, adding 0.32g (1.84mmol) 2, 4-toluene diisocyanate electrophoretic particle preparation and its Application in electronic ink 31 ester and 0.02g (0.03mmol) OP-10 to prepare oil phase. Add the oil phase to 100mL of water at a certain stirring speed. Then 1.46g (10.00mmol) trethylenetetraamine was added and reacted for 3min to obtain microcapsules covered with electrophoretic dispersion. The microcapsules were washed with water for several times to obtain electronic Ink (tt-e-ink) microcapsules prepared by interfacial polymerization.