How to choose the type of bead mills

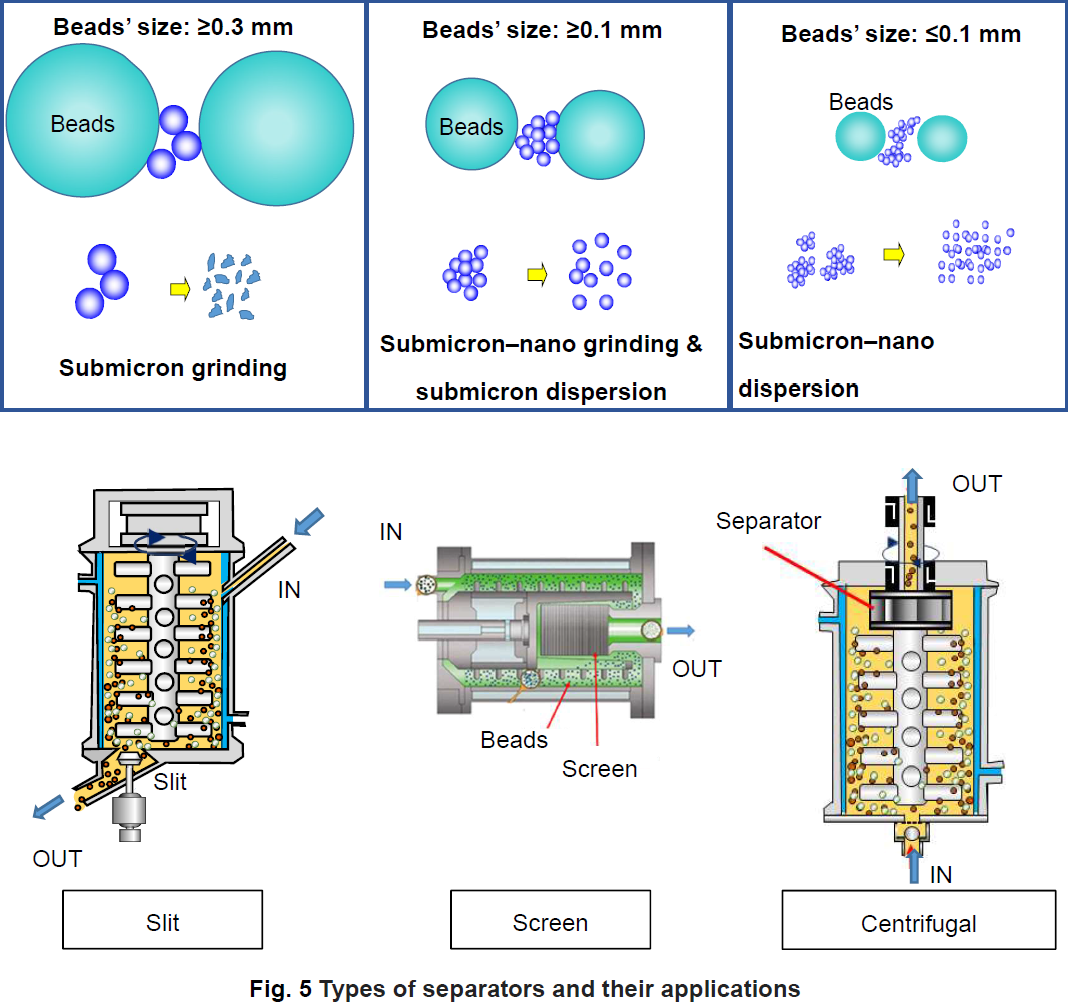

As explained in the previous section, it is very important to choose proper bead size according to the purpose of processing. It is, therefore, important to select the best method of bead separation, which depends on the bead size.

Selection of the bead separation methods is, therefore, one of the most important factors for choosing the type of bead mills. Bead separation methods are generally grouped into slit, screen, and centrifugation methods, each of which has its preferable bead size. The three methods are explained in the following sections.

Slit separator

This is a method of separating beads from the slurry by a narrow slit gap at the slurry exit. The gap width is about one-third the bead diameter. A bead mill equipped with a slit separator functions with beads of the size of 0.3 mm or larger. This is because when the slit gap is narrower than 0.1 mm, for beads smaller than 0.3 mm, the slit clogs due to entrapment of relatively coarse particles, and the required pressure for slurry to pass through the slit rises largely. This method allows a stable operation without leaking beads even for a highly viscous slurry.

Screen separator

This separator, similar to the slit separator, utilizes the geometry of narrow passes of a screen at the slurry exit. The screen has a mesh with a texture of metal wires that provide narrow gaps for separation of the beads from the slurry. A bead mill equipped with this method functions with beads of size of 0.1 mm or larger. This method can use smaller beads than the slit method, because the screen has a larger opening area for the slurry passage. However, in case of using beads smaller than 0.1 mm, a finer screen is needed, and it tends to clog due to coarse particles in the slurry. Clogging with this method occurs as likely as with the slit method. This method is less favorable for a high viscous slurry.

Centrifugal separator

This is a separator that utilizes centrifugal force for separating beads from the slurry. The separator has plates that line up in a circular manner. The plates induce a rotation of fluid, which is favorable for bead separation. Since the bead has a density 4 to 5 times that of the slurry, the centrifugal force effectively acts as gravitational screening. An important feature of this method is that this method has no narrow gap. There is no need for slurry to pass through a narrow gap: therefore, no clogging occurs even with beads as small as 15 or 30 μm. Thus, this is the best bead separator for micro bead processing applied to 3. How to choose the type of bead mills dispersion of submicron- and nanometer-size particles. It is also applied to grinding particles of the size of submicron or nanometers.

Comparison of the types of separators

When planning grinding or dispersing operation of the bead mill, one should first determine an adequate bead size. The bead size is, as mentioned before, selected according to properties of materials and purpose of the processing. After selecting the bead size, the type of separators is to be selected for the best fit for the bead selected.

Since each of the bead separators has its own strong and weak points, the type of separator is to be selected according to its characteristics and the selected bead size. In the case of grinding particles of micron or submicron in the final size, slit and screen separators are adopted because the grinding practice requires relatively large beads. In the case of dispersing particles of submicron in the final size, screen and centrifugal separators are adopted because the favorable bead size is less than 0.3 mm. In the case of dispersing nanoparticles, a centrifugal separator is selected since the bead size required for dispersion is less than 100 μm.