Ceramic Silicon Nitride(Si3N4)

Silicon Nitride (Si3N4) Ceramic Balls are formed from a new material suitable for applications where high loads, high speeds and extreme temperatures are factors. Long life and the need for minimal lubrication make this material appropriate for extreme applications. Silicon Nitride is non-porous, non-magnetic, non corrosive, lighter than steel and, in ball form, is harder than steel. Because ceramic balls are non-porous they are virtually frictionless and are capable of spinning faster than steel balls.

Diverse Industry Usage

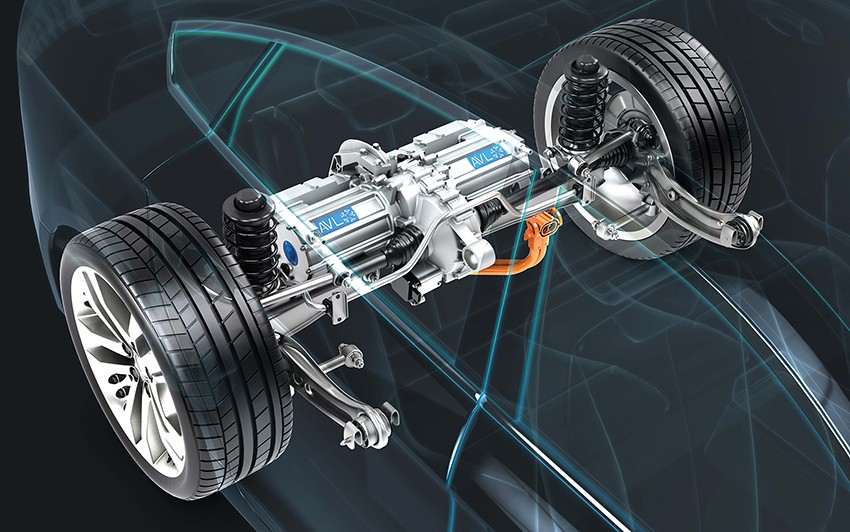

Silicon nitride balls are used in wide range of expanding applications including electric vehicles, wind power generators, semiconductor manufacturing equipment and others.

When an electric current passes through the inside of a rotating bearing on an electric vehicle motor, arcing occurs and the contact surface is damaged. To solve this problem, bearings using silicon nitride balls are used due to the excellent insulative properties.

The small ball bearings in fishing reels serve the same purpose in baitcasting or spinning reels as they do in any other mechanical device - reduction of friction between moving parts. So they fall into the classification of "anti-friction bearings". Without them life would be far more difficult. Any time two objects come in contact while moving across one another friction is generated and the resulting force is resistance against the motion. Motion is slowed or stopped all together.

As the trend for wind turbine farms increase in size and power generation, the tower height, blade length, and generator size have all increased in size and in load requirements.

Silicon nitride ball bearings have the durability and load carrying capacity to bring an efficient solution to meet these demands.

The longevity of silicon nitride balls further lends itself to reduce the risk of unscheduled maintenance, which is costly given the height and location of wind towers.

Silicon nitride ball bearings are used in semi-conductor manufacturing equipment due to the high speeds and low lubrication conditions.

As compared to using steel balls, the use of silicon nitride balls in the bearings has shown to increase bearing life by 50% or more.

By reducing the replacement frequency and maintenance costs, the total life cycle cost of the manufacturing process can be reduced.

By using silicon nitride balls on the wheel hub (bottom bracket) of your bicycle, you can reduce friction, reduce weight and extend bearing life.

SANXIN ceramic silicon nitride balls are widely used, It has stable performance, good consistency, the size 0.4mm to 100mm, from grade G5-G100.

Most are black silicon nitride balls, if necessary, we can also provide gray ones.

We have mass stock, can deliver anytime you want.

Meet the requirements of various specifications and non-standard sizes.